6. Boto e tsokotsoa ka bo eona, 'me bophara ba tlhōrō ea leqhubu la tin bo ka fetoloa ho fokotsa bongata ba tin oxidation.

7. 1800mm mefuta e atolositsoeng ea sethala sa boraro (e mene) preheating, infrared (moea o chesang) taolo ea mocheso e ikemetseng ea PID, Esita le ho futhumatsa, ho bolokehile ebile ho tsitsitse.

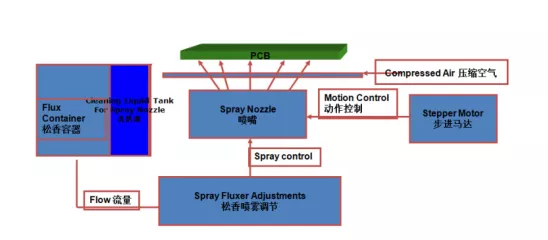

◆ Ka nozzle ea Lumina (Japan), sebaka sa spray ke 20-65mm, bophahamo ba nozzle ke 50-80mm, 'me tekanyo e phahameng ea ho phalla ke 60ml / min.

◆ E sebelisa filthara ea AirTAC (Taiwan), pointer gauge e bonts'a khatello ea moea, liphaephe tsohle tsa tsamaiso ea spray ke liphaephe tse sireletsang ho bola ha acid le alkali.

◆ Ho fafatsa tsamaiso e amohela scanning ho fafatsa mokhoa, moedi fapoha le ho kena mahlo a ho kena li kopanngoa ho laola, 'me PCB e ka tsela e iketsang lemoha ka ho fafatsa inductive ho ea ka lebelo le bophara ba PCB, e le hore ho wetting mefuta e fapaneng ya flux ka finyella phello e molemo ka ho fetisisa.Hlooho ea ho fafatsa ka Inlet le mochini o hatang li sebetsa hantle, li tsitsitse ebile lia tšepahala.

◆ Stainless steel bent form tray e sebelisoa ka tlas'a hlooho ea spray bakeng sa ho kenya metsi a litšila le a phallang, a ka ntšoang le ho hloekisoa ka ho rata.

◆ The air extraction system is a superimposed automatic recovery system with three layers of stainless steel wire mesh filtration ho fokotsa masala a thibelang phaephe e ntshang moya ka ho sebedisa mokelikeli ho sefa phallo e feteletseng.

◆ Thipa ea moea ea pneumatic, e otlang phallo e feteletseng nakong ea ho fafatsa ka tanka ea ho hlaphoheloa ho thibela phallo ho kena sebakeng sa preheating le ho netefatsa tšireletso ea tlhahiso.

◆ Ts'ehetso eohle ea tšepe e sa hloekang + aluminium alloy alloy, ho hloekisa habonolo le tlhokomelo, khanyetso e matla ea kutu, e tšoarellang.

Sistimi ea Welding

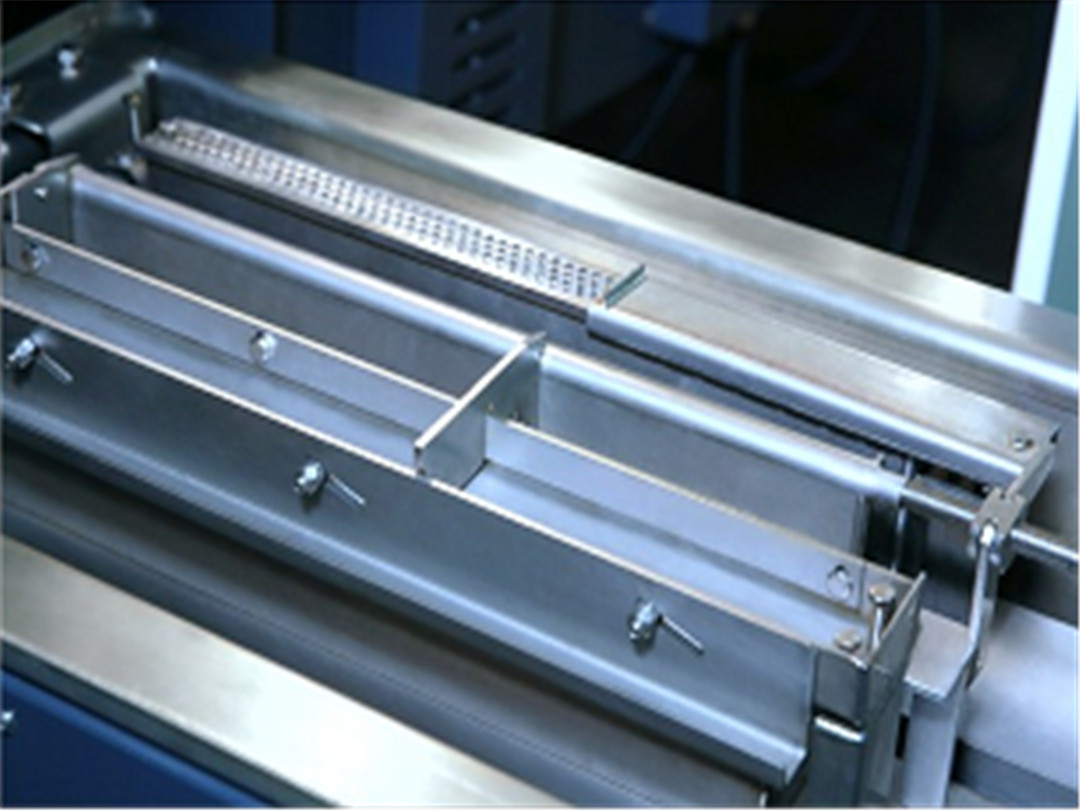

1. 4mm SUS316L Lebone la sebopi le tsoang kantle ho naha, moralo o mocha oa sebopi, ponahalo e ntle, e bonolo ho e hloekisa, poleiti e futhumatsang ea tšepe, lesela la sebopi ha le holofala.

2. Leqhubu la tšitiso, jete e tataisoang, solder e ntle ka ho fetisisa ea likarolo tsa SMD, leqhubu la maqhubu le boreleli joalo ka seipone.

3. Bophara ba tlhoro ea maqhubu bo ka fetoloa ho fokotsa bongata ba tin oxidation, 'me filthara e ka huleloa ntle le ho harola molomo.

4. Eketsa sekoahelo sa anti-oxidation sebakeng sa mochini oa impeller ho fokotsa bongata ba tin oxidation e bakoang ke ho potoloha ha leqhubu la impeller.

5. The impeller shaft le wave motor e ka aroloa ka thoko ntle le ho qhaqholla kanale ea tin (li-brand tse ling tsa wave soldering li ke ke tsa etsa moralo ona)

Tsamaiso ea Lipalangoang

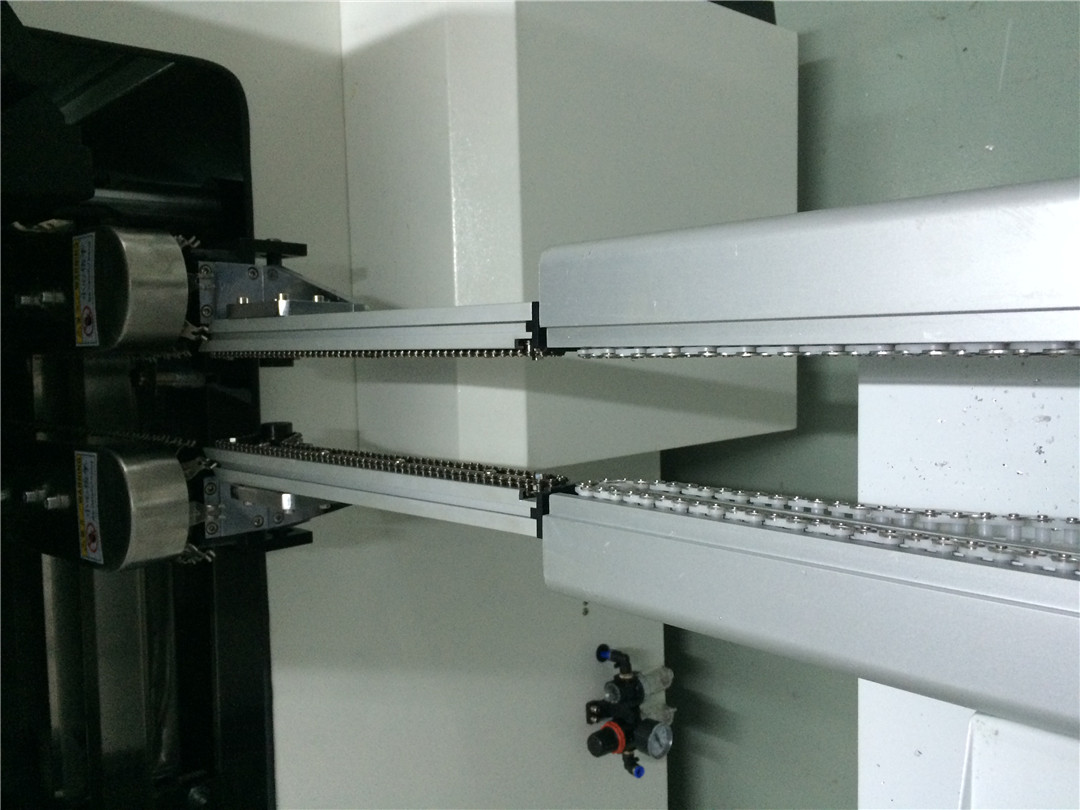

Lisebelisoa tse hloekileng tsa aluminium tse iphepang ka boiketsetso le sesebelisoa se hokahanyang, phepelo e boreleli le e tsitsitseng, phetoho e kholo

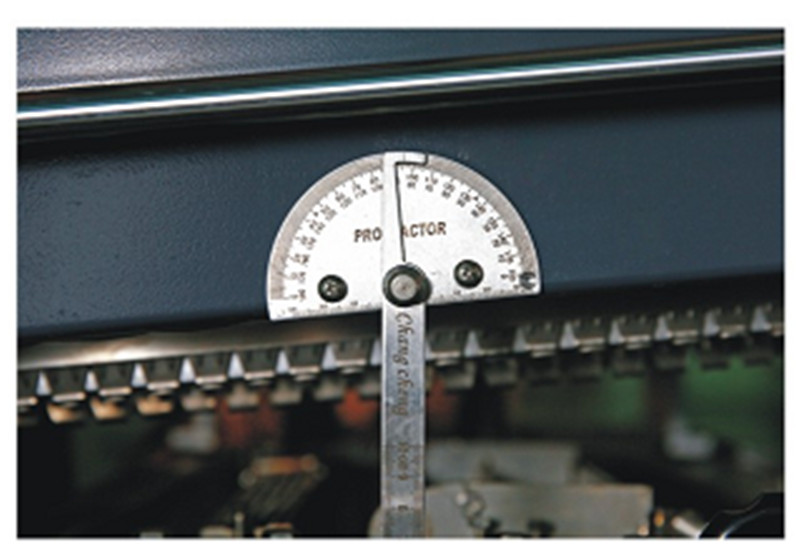

Seporo sa tataiso se na le sesebelisoa sa sona sa ho sekama, se ka lekola ka nepo sekhutlo le ho laola boleng ba boto.

Titanium alloy claw hooks e etsa bonnete ba hore thini e ke ke ea silafatsoa le ka mohla, 'me methati e meraro e tsitsitseng e tiisa hore liporo tsa tataiso li ke ke tsa chesoa, e leng se thibelang ka katleho hore litšepe tse tataisang li se ke tsa oa le ho tlama.

◆Sefaha sa koporo sa 4mm se etsa hore mokhoa oa lipalangoang o be bonolo le o tsitsitseng.(Bongata ba lihlahisoa tse ling li sebelisa lisebelisoa tsa tšepe tse sa hloekang, tse ke keng tsa tiisa lipalangoang ka nako e telele.)

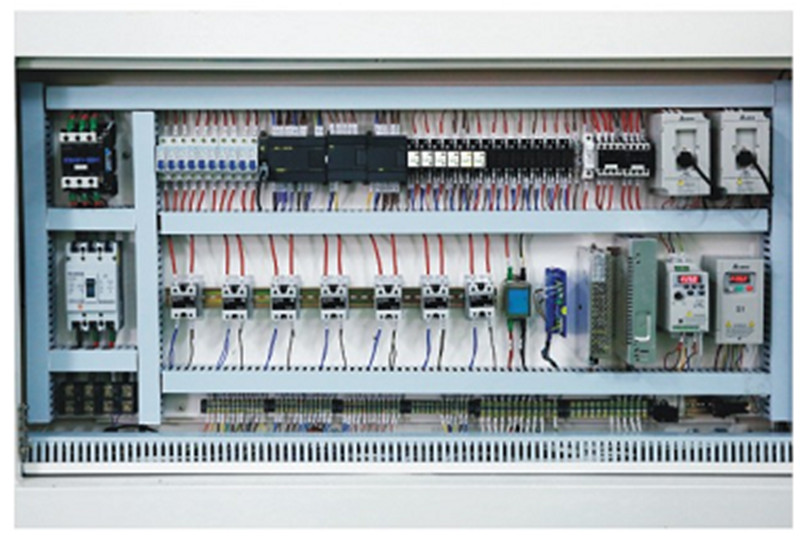

Sistimi e nolofalitsoeng ea ts'ebetso e bonolo hore basebetsi ba sebetse, mme sistimi ea taolo ea PC + PLC e etsa hore taolo ea mocheso e nepahale le ho tsitsisa.

Lisebelisoa tsa motlakase ke lihlahisoa tse tsebahalang lapeng le kantle ho naha, 'me ea mantlha Siemens PLC e tiisa hore sistimi e bolokehile ebile e tsitsitse.

Taolo ea mocheso e amohela algorithm ea taolo ea PID, ha ho na tlhoko ea ho beha liparamente tsa PID, ho nepahala ha taolo e phahameng.

Litekanyetso tsa tekheniki

| Mohlala | CY-350B/T | CY-450B/T |

| Nomoro ea sebaka sa ho futhumatsa | Enjene e hatang kapa moqomo o se nang molamu | |

| Palo ea sebaka sa ho pholisa | LILITHARA tse 6 | |

| Khatello ea moea ea phallo | 3-5BAR | |

| Preheating Mode | Moea o chesang o bobebe / infrared | |

| Nomoro ea Sebaka sa Preheating | 4 karolo | |

| Preheating Length | 1800 limilimithara | |

| Nako ea ho futhumatsa | Hoo e ka bang metsotso e 15 | |

| PCB boholo bophara | 350 limilimithara | 450 limilimithara |

| Tataisa mefuta e mengata | 50-350 limilimithara | 50-450 limilimithara |

| Lebelo la Conveyor | 0-2000mm/min | |

| Conveyor Height | 750±20mm | |

| Tataiso ea lipalangoang | L→R(R→L) | |

| Mokhoa oa phetiso | 4-7° | |

| Mocheso oa solder | 9KW (Mocheso oa kamore-300℃) | |

| Matla a solder | 400Kg | 500Kg |

| Mokhoa oa ho laola | Brand Computer (Windowsoperating system)+Siemens PLC | |

| Lebelo la conveyor | 3∮ AC380V 90W, Lebitso: Tai Chuang | |

| Enjene ea maqhubu | 3∮ AC220V 360W * 2pcs, Lebitso: Tai Chuang | |

| Pompo ea ho hloekisa menoana | 1P AC220V 10W | |

| Menoana | Special titanium alloy double groove claw | |

| Sistimi ea ho pholisa | Pholiso ea moea e qobelloang | |

| Phepelo ea motlakase | 5-terata 3-mohato 380V 50/60Hz | |

| Qala matla | 38kw | |

| Matla a tloaelehileng a ho sebetsa | Hoo e ka bang 10Kw | |

| Mokhoa oa ho laola mocheso | PID e felletseng ea komporo e koetsoeng taolo ea loop, drive ea SSR | |

| Alamo e sa tloaelehang | Mocheso o sa tloaelehang (o phahameng haholo kapa o tlase haholo ka mor'a mocheso o sa khaotseng) | |

| Leseli la mebala e meraro | Leseli la pontšo ea mebala e meraro: mocheso o mosehla;mocheso o sa feleng;khubelu-e sa tloaelehang | |

| Boima ba 'mele | Hoo e ka bang 1800Kg | Hoo e ka bang 2000Kg |

| Installationdimension (mm) | L4300×W1530×H1700mm | |

| Litlhoko tsa moea oa ho tsoa | 10 cube / min 2 aisle∮200mm | |